A steam turbine island is a central part of a thermal power plant, where energy from steam is converted into mechanical and subsequently electrical energy. Understanding its components and functionality is crucial for engineers, operators, and anyone interested in power generation. This article explores the structure, components, and operation of a steam turbine island in detail.

Overview of a Steam Turbine Island

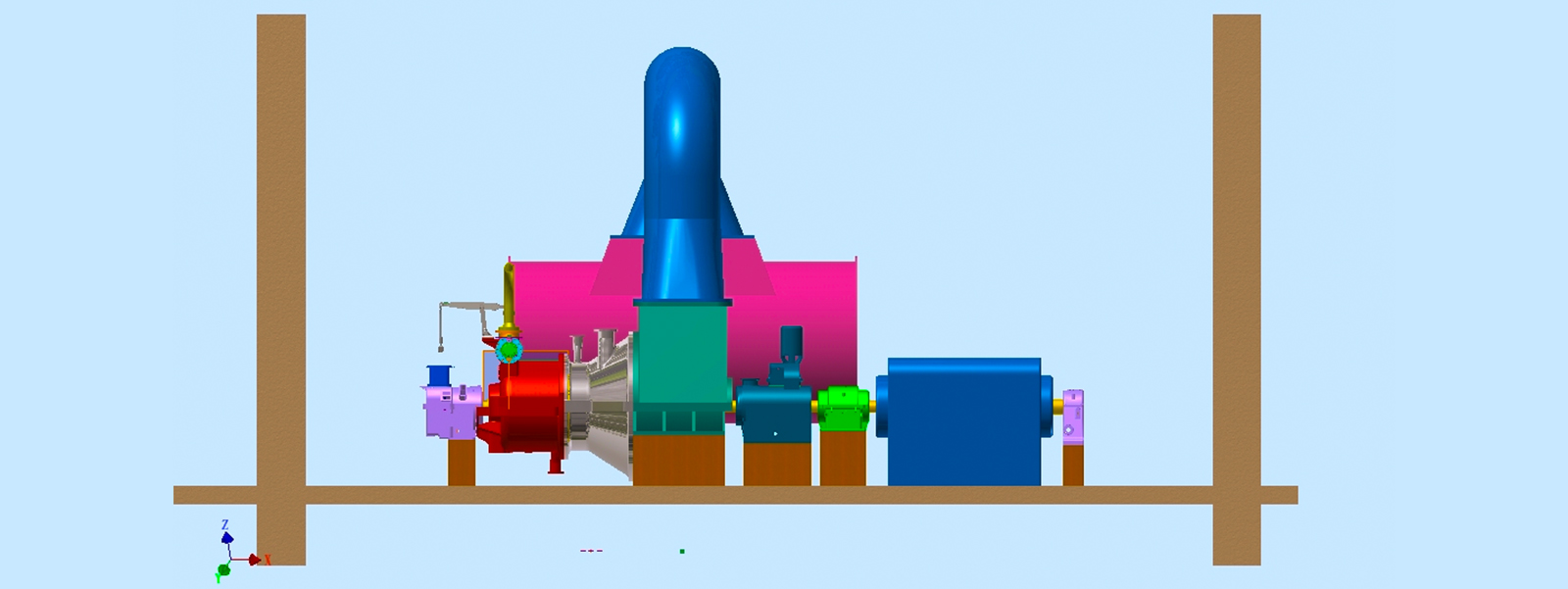

A steam turbine island refers to the entire set of equipment associated with the steam turbine in a power plant. It is a self-contained system that includes the turbine itself, generators, condensers, pumps, and auxiliary equipment. The primary function of this island is to convert high-pressure, high-temperature steam into rotational energy that drives the electrical generator.

Typically, a steam turbine island receives steam from the boiler at high pressure and temperature. The steam passes through the turbine stages, where its energy is gradually extracted. The exhausted steam is then condensed back into water, which is pumped back to the boiler, creating a continuous cycle.

Main Components of a Steam Turbine Island

A steam turbine island is composed of several key components, each performing specific functions to ensure efficient energy conversion. Understanding these components is essential for maintenance, troubleshooting, and optimization.

Steam Turbine

The steam turbine is the core component of the island. It converts thermal energy from steam into mechanical rotational energy. Turbines consist of multiple stages, including high-pressure (HP), intermediate-pressure (IP), and low-pressure (LP) sections. Each stage extracts energy from the steam by expanding it across a series of blades mounted on a rotating shaft.

The HP section handles steam directly from the boiler at extremely high temperatures and pressures. After passing through the HP stage, the steam moves to the IP and then LP sections, gradually reducing in temperature and pressure while performing work on the turbine shaft. Modern turbines are designed to minimize energy losses and maximize efficiency.

Generator

Attached directly to the turbine shaft is the generator, which converts mechanical energy from the turbine into electrical energy. The generator typically consists of a rotor and stator, where the rotor rotates inside a magnetic field, inducing an electrical current in the stator windings. This electricity is then transmitted to the power grid.

Condenser

The condenser plays a critical role in maintaining the efficiency of the steam turbine island. Its primary function is to condense the low-pressure exhaust steam from the turbine into water. By converting steam back into water, the condenser reduces backpressure on the turbine, allowing for more energy extraction.

Condensers often use cooling water from a river, lake, or cooling tower to remove heat from the exhaust steam. Efficient condensation is vital for preventing energy loss and ensuring a steady supply of feedwater to the boiler.

Feedwater Pumps

Feedwater pumps are essential for maintaining the circulation of water within the steam turbine island. After the steam is condensed in the condenser, these pumps move the water back to the boiler. High-pressure feedwater pumps ensure that water reaches the boiler at the correct pressure and flow rate, which is necessary for stable and efficient operation.

Auxiliary Systems

Several auxiliary systems support the operation of a steam turbine island. These include lubrication systems, control systems, and steam extraction systems.

- Lubrication systems provide oil to turbine bearings, reducing friction and wear.

- Control systems regulate the operation of the turbine, including speed, load, and temperature.

- Steam extraction systems supply intermediate-pressure steam for feedwater heating or other plant processes, enhancing overall efficiency.

Functionality of a Steam Turbine Island

The operation of a steam turbine island can be described as a continuous energy conversion process. Steam generated in the boiler enters the turbine at high pressure and temperature. As it flows through the turbine blades, the thermal energy is converted into mechanical energy, rotating the turbine shaft.

The mechanical energy is then transferred to the generator, producing electricity. After passing through the turbine, the low-energy steam enters the condenser, where it is cooled and converted back into water. The feedwater pumps return this water to the boiler, completing the cycle.

Efficiency Considerations

Efficiency in a steam turbine island depends on multiple factors, including steam conditions, turbine design, and condenser performance. Higher steam temperatures and pressures generally improve energy conversion but require advanced materials and precise engineering. Additionally, minimizing energy losses in the condenser and maintaining optimal flow through pumps and auxiliary systems are critical for maximizing efficiency.

Safety and Monitoring

Safety is paramount in the operation of a steam turbine island. Modern plants are equipped with sensors and monitoring systems to detect abnormal conditions such as high vibration, excessive temperature, or pressure fluctuations. Automatic shutdown mechanisms protect both the turbine and surrounding equipment in case of emergencies. Routine inspections and maintenance schedules are also vital to ensure the longevity and safe operation of the turbine island.

Integration with the Power Plant

A steam turbine island does not operate in isolation. It is integrated with other plant systems, including the boiler, cooling systems, and electrical grid. Proper synchronization with the grid ensures that electricity is supplied reliably. Additionally, heat recovery systems and auxiliary processes are often tied to the turbine island to optimize overall plant efficiency.

Conclusion

The steam turbine island is a complex yet highly efficient system that forms the backbone of thermal power generation. By understanding its components—from the turbine and generator to the condenser, pumps, and auxiliary systems—engineers and operators can optimize performance, enhance safety, and ensure reliable electricity production. The functionality of a steam turbine island highlights the importance of energy conversion technology in modern power plants, emphasizing precision engineering, careful monitoring, and efficient system design.

A deep understanding of the steam turbine island not only supports operational excellence but also contributes to innovation in power plant design, efficiency improvements, and sustainable energy management. Whether for education, maintenance, or design purposes, mastering the workings of a steam turbine island is key to advancing the field of power generation.